- ProductsProducts

Since the start of modern mechanical engineering, numerous patents, new developments and innovative details can be attributed to the inventive spirit of INDEX. Perhaps that is the reason why we are always looking to push our limits and be better. Our ultimate goal is to build the best turning machines through top performance. Check out the current INDEX & TRAUB product portfolio including production turning machines, turn-mill centers, turn-grind centers, vertical turning machines and CNC multi-spindle turning machines.

- Machine Selector

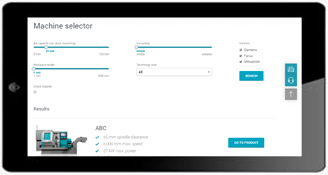

Machine Selector

Machine SelectorFind the right machine for your use with our machine selector.

The selector helps you to localize suitable machines for your usage.

- Universal turning machines

Universal turning machines

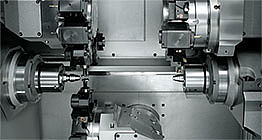

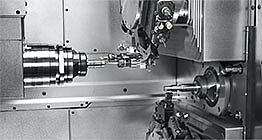

Universal turning machinesThe INDEX & TRAUB universal turning machine has an excellent reputation around the world when it comes to the machining of large chuck, shaft, and bar workpieces. Through precision, efficiency, short cycle times, and ease of use, these universal turning machines have set a standard in their class.

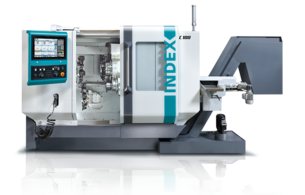

- INDEX B400

INDEX B400

INDEX B400- 82 mm spindle clearance

- 315 mm chuck diameter

- 750 mm turning length

- INDEX B500

INDEX B500

INDEX B500- 102 mm spindle clearance

- 400 mm chuck diameter

- 750 mm turning length

- TRAUB TNA400

TRAUB TNA400

TRAUB TNA400- 82 mm spindle clearance

- 315 mm chuck diameter

- 750 mm turning length

- TRAUB TNA500

TRAUB TNA500

TRAUB TNA500- 102 mm spindle clearance

- 400 mm chuck diameter

- 750 mm turning length

- INDEX B400

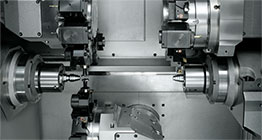

- Turn-mill centers

Turn-mill centers

Turn-mill centersINDEX & TRAUB turn-mill centers set the standard for economic, high-precision solutions tailored to the customer's needs. Standards ranging from the classic production turning machine to tailor-made machining cells equipped with handling units. For the machining of simple to highly complex parts, in small to large lot sizes, INDEX consistently offers economically and technologically superior solutions.

- INDEX G200.2

G200.2

G200.2- 65 mm spindle clearance

- 165 mm chuck diameter

- 660 mm turning length

- INDEX G200.3 / INDEX G220

G200.3/ G220

G200.3/ G220- Spindle clearance 76 mm / 90 mm

- Chuck diameter 230 mm

- 207 Nm max. torque

- Turning length 900 mm / 1.200 mm

- INDEX G300 / INDEX G320

G300/ G320

G300/ G320- Spindle clearance 102 mm

- Chuck diameter 250 mm

- Turning length 1400 mm

- INDEX G400 / INDEX G420

G400/ G420

G400/ G420- Spindle clearance 120 mm

- Chuck diameter 400 mm

- 1000 Nm max. torque

- Turning length 1600 mm / 2300 mm

- INDEX G500 / INDEX G520

G500/ G520

G500/ G520- Spindle clearance 120 mm

- Chuck diameter 500 mm

- 2000 Nm max. torque

- Turning length 1600 / 2300 mm

- INDEX R200

R200

R200- 65 mm bar diameter

- 5,000 rpm speed

- 24 kW max. power

- 190 Nm max. torque

- INDEX R300

R300

R300- 102 mm bar diameter

- 3,500 rpm max. speed

- 52 kW max. power

- 690 Nm max. torque

- TRAUB TNX200 / TRAUB TNX220

TNX200 / TNX220

TNX200 / TNX220- Spindle clearance 76 mm

- Chuck diameter 230 mm

- 207 Nm max. torque

- Turning length 900 mm

- TRAUB TNX65

TNX65

TNX65- 65 mm max. spindle clearance

- 175 mm max. chuck diameter

- 650 mm turning length

- Milling unit or turret selectable

- INDEX iXtoolsINDEX iXtools

- INDEX G200.2

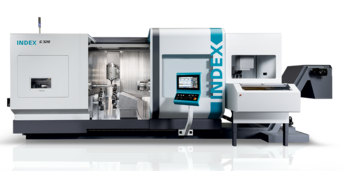

- Production turning machines

Production turning machines

Production turning machinesINDEX & TRAUB automatic turning machines are especially designed for fast, cost-effective production of standard automated turned parts and complex CNC turned parts. The flexibility of CNC technology, combined with the high speed of classic automation, allows the production of small to medium lot sizes at competitive prices.

- INDEX C100

INDEX C100

INDEX C100- 42 mm spindle clearance

- 110 mm chuck diameter

- 400 mm turning length

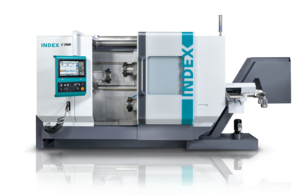

- INDEX C200

INDEX C200

INDEX C200- 65 (90) mm spindle clearance

- 160 mm chuck diameter

- 550 mm turning length

- INDEX ABC

INDEX ABC

INDEX ABC- Spindle clearance 65 mm

- 6,000 rpm max. speed

- 27 kW max. power

- 145 Nm max. torque

- TRAUB TNK40

TRAUB TNK40

TRAUB TNK40- Fixed headstock on main spindle

- Spindle clearance up to Ø 40 mm

- 8,000 rpm max. speed

- 35 Nm max. torque

- Hydraulic hollow clamping cylinder

- INDEX C100

- Multi-spindle machines

Multi-spindle machines

Multi-spindle machinesINDEX Multi-spindle machines combine the advantages of CNC technology with those of cam-controlled machines. They can be used not only for series production of a wide range of precision parts but also for small series due to their extremely short setup times. Whatever the application, these multi spindle turning machines impress with their high performance.

- INDEX MS16-6 / MS16-6 Plus

INDEX MS16-6 / MS16-6 Plus

INDEX MS16-6 / MS16-6 Plus- 16 / 22 mm bar diameter

- 10,000 rpm max. speed

- 15 kW max. power

- 18 Nm max. torque

- INDEX MS24-6

INDEX MS24-6

INDEX MS24-6- 24 mm bar diameter

- 10,000 rpm

- 15 kW max. power

- 18 Nm max. torque

- INDEX MS24-8

INDEX MS24-8

INDEX MS24-8- 24 mm bar diameter

- 10,000 rpm max. speed

- 15 kW max. power

- 18 Nm max. torque

- INDEX MS32-6

INDEX MS32-6

INDEX MS32-6- 32 mm bar diameter

- 8,000 rpm max. speed

- 19 kW max. power

- 40 Nm max. torque

- INDEX MS40-6

INDEX MS40-6

INDEX MS40-6- 40 mm bar diameter

- 7,000 rpm max. speed

- 24 kW max. power

- 57 Nm max. torque

- INDEX MS40-8

INDEX MS40-8

INDEX MS40-8- 40 mm bar diameter

- 7,000 rpm max. speed

- 24 kW max. power

- 57 Nm max. torque

- INDEX MS52-6

INDEX MS52-6

INDEX MS52-6- 52 mm bar diameter

- 5,000 rpm max. speed

- 30 kW max. power

- 130 Nm max. torque

- INDEX MS16-6 / MS16-6 Plus

- Sliding headstock machines

Sliding headstock machines

Sliding headstock machinesCNC sliding headstock machines from TRAUB are designed for exact and productive manufacturing of long and slim parts with a maximum diameter of 32 mm. The multitude of variants, miniturization and precision of the work pieces are but a few of the demands on a CNC swiss turning center. The TNL-series is characterized through high performance in combination with easy setup and programming.

- TRAUB TNL32 compact

TRAUB TNL32 compact

TRAUB TNL32 compact- 32 mm spindle clearance

- 8,000 rpm max. speed

- 220 mm max. Z-travel

- TRAUB TNL12

TNL12

TNL12- 13 mm spindle clearance

- 12,000 rpm max. speed

- 130 mm max. Z-travel

- TRAUB TNL12 lean

TRAUB TNL12 lean

TRAUB TNL12 lean- 13 mm spindle clearance

- 12,000 rpm max. speed

- 130 mm max. Z-travel

- TRAUB TNL20

TNL20

TNL20- 20 mm spindle clearance

- 10,000 rpm max. speed

- 205 mm max. Z-travel

- TRAUB TNL32

TNL32

TNL32- 32 mm spindle clearance

- 8,000 rpm max. speed

- 305 mm max. Z-travel

- TRAUB TNL32 compact

- Tool holders

Tool holders

Tool holdersYou have a machine from us and look for the matching tool holders?

Of course, we have the perfect holders for you and even more: as a cost-effective solution we have compiled perfect tool holder packages.

- Automation solutions

Intelligent automation solutions

Intelligent automation solutionsEven more flexibility and efficiency. Find out more about our bar loading magazines and our machine-integrated, automated robot, and customized solutions.

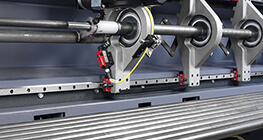

- Bar loader

Bar loading

Bar loadingAlways well loaded. The bar loading magazines are ideally adjusted to the INDEX & TRAUB CNC turning machines for single-spindle and multi-spindle turning operations. They convince with short set-up times , fast bar change and a backlash-free guidance of the bar for high surface qualities.

- Machine-integrated solutions

Machine-integrated solutions

Machine-integrated solutionsOur machines offer different methods for workpiece removal – quickly, safely, and gently.

- Automated robot solutions

Automated robot solutions

Automated robot solutionsIntelligent automation – even more flexibility and efficiency

- Customized solutions

Customized solutions

Customized solutionsLet our experts help you find the right solution for your specific requirements – with their many years of experience in a wide range of sectors.

- Bar loader

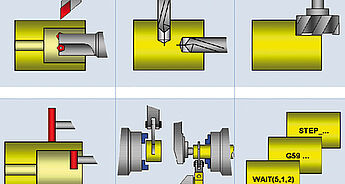

- Control and software

Control and software

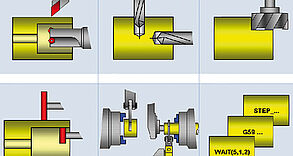

Control and softwareDiscover the new iXpanel – i4.0 ready operating system for direct communication with your business organization and machine controllers. Or find out more about our controllers, our outstanding programming and control software, or our technology packages.

- INDEX iXpanel

iXpanel i4.0 ready

iXpanel i4.0 readyThe operating system for direct communication with your business organization. Focus on control and production – Industry 4.0 included.

- Control

CNC controllers

CNC controllersFind out more about our Siemens, FANUC and TRAUB CNC controllers.

- Software

Programmier- und Simulationssoftware

Programmier- und SimulationssoftwareExcellent programming and simulation software solutions for INDEX & TRAUB machine tools.

- Technology Packages

Technologiepakete INDEX TRAUB

Technologiepakete INDEX TRAUBTechnology software on INDEX and TRAUB machines for the economical production of workpieces.

- INDEX iXpanel

- Special offer machines

INDEX and TRAUB Special Offer Machines

INDEX and TRAUB Special Offer MachinesMachines previously demonstrated at trade shows or in our showroom provide all of the benefits of the world’s best turning centers, but at a reduced investment level. Each of these machines has been fully certified and has a low level of operating hours in a non-production environment.

- Second-hand machines

Second-hand machines

Second-hand machinesOur used machines are modernized by our qualified employees and their decades of experience in mechanical engineering. Components are usually completely dismantled, cleaned, and repainted as required.

The interior gets a “makeover” treatment.

- Machine Selector

- Technology & solutions

- iXservices

- News & Media

- Company

- iXworld

INDEX - better.parts.faster.

With its strong INDEX and TRAUB brands, the INDEX Group is today one of the world’s leading manufacturers of CNC turning machines, automatic lathes, multi-spindle lathes and turn-mill centers.

Turning and milling solutions

Find out more about our productive standard and special solutions to manufacture economically and to increase your business success sustainably.

Everything revolves around you!

You are the centre of our focus. We personally stand by your side from the first information of the sales process up to cycle time optimization or a special process integration. We will be pleased to advise you on your suitable manufacturing solution.

start request

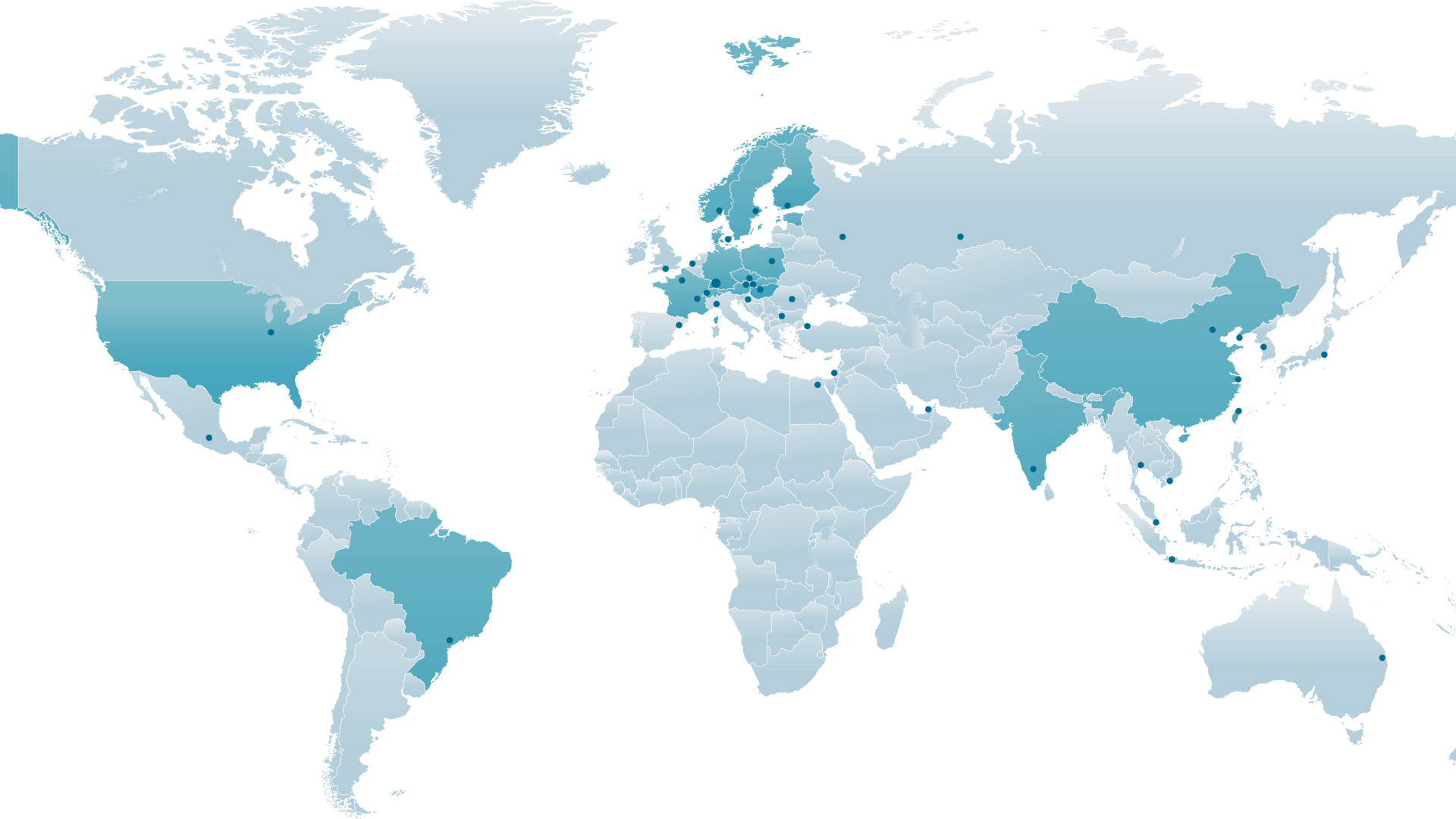

Global presence

The Company Group in Esslingen has 80 sites worldwide with five production sites and seven international sales and service companies as well as an extensive retailer network.